Circular Knitting Machine Parts

- Home

- Circular Knitting Machine Parts

Featured Project

The ultimate clothing to see the world in.

Pede torquent ipsum aliquam sodales montes ac laoreet rhoncus euismod ligula egestas. Tortor gravida nunc aliquam curabitur auctor habitant viverra. Sagittis eros est tristique maximus ornare nisi.

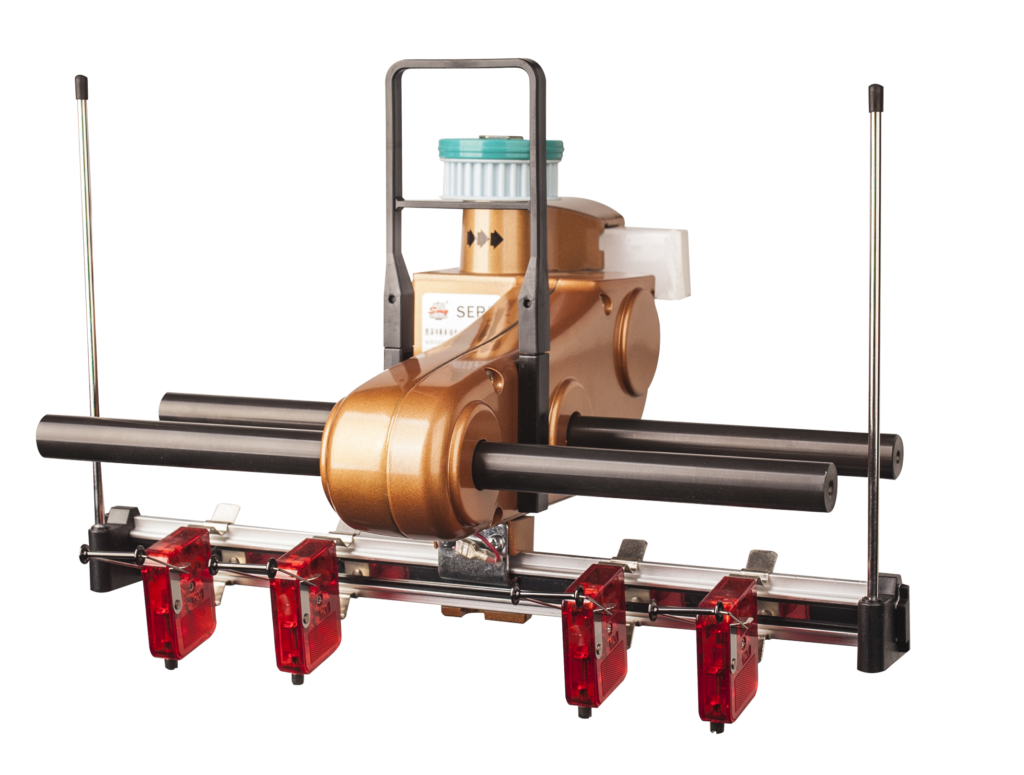

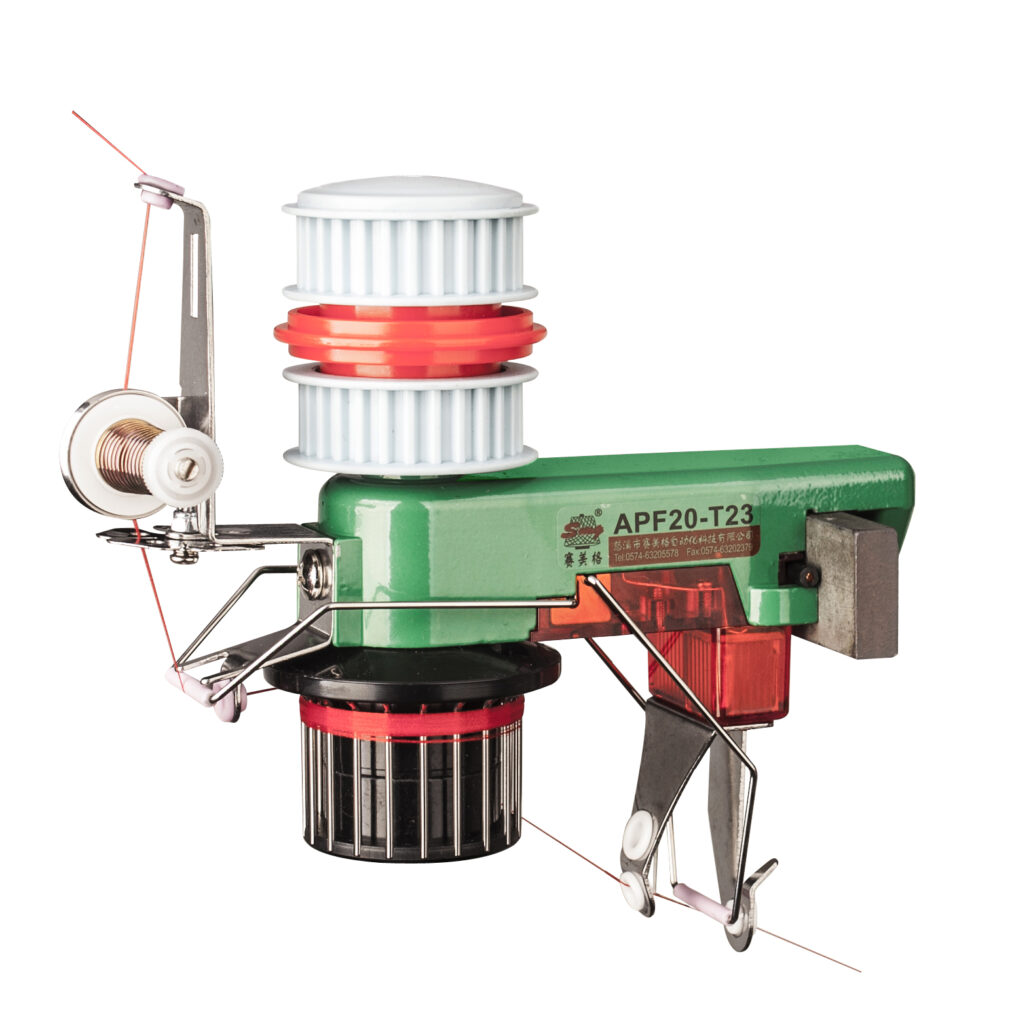

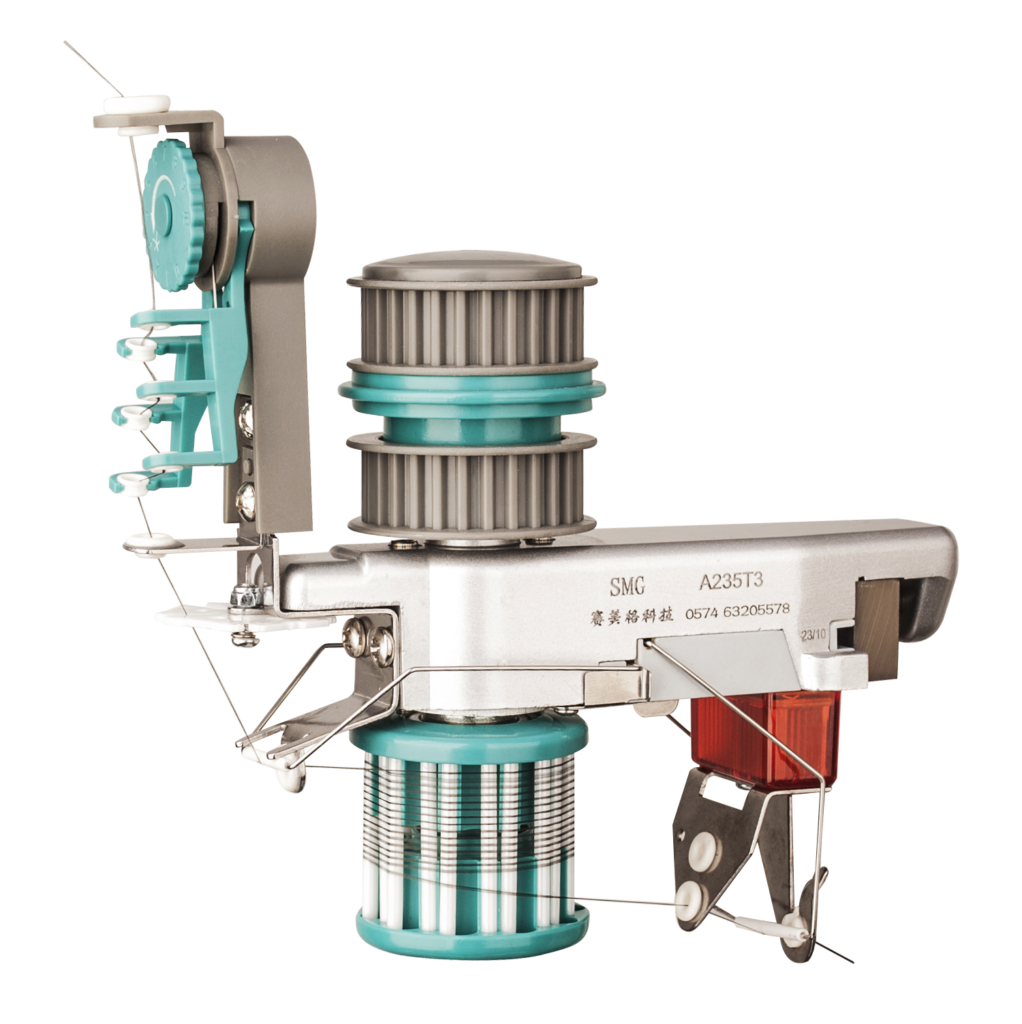

The Role of Yarn Feeders in Circular Knitting Machines

The yarn feeder ensures a continuous and even supply of yarn from the yarn creel or bobbins to the knitting needles, enabling uninterrupted knitting.

2. Tension Control

It regulates the yarn tension to maintain optimal conditions during the knitting process. Proper tension prevents defects such as loose loops, tight stitches, or dropped stitches in the fabric.

3. Multiple Yarn Feeding

In multi-feeder systems, yarn feeders can supply multiple yarns simultaneously to different knitting paths. This enhances production speed and enables complex pattern creation.

4. Adaptation for Different Yarn Types

Specialized yarn feeders, such as those for elastic yarns or fancy yarns, are designed to handle specific yarn types without damaging their properties, ensuring consistent knitting quality.

5. Support for Patterned Fabrics

Certain yarn feeders allow the use of multiple colors or fancy yarns, supporting jacquard knitting and other decorative fabric production.

6. Prevention of Yarn Breakage

Yarn feeders include features like tensioners and yarn guides to minimize friction and reduce the risk of yarn breakage during the knitting process.

7. Maintaining High-Speed Operation

During high-speed knitting, the yarn feeder ensures stable and consistent yarn delivery, preventing interruptions or defects caused by uneven feeding.