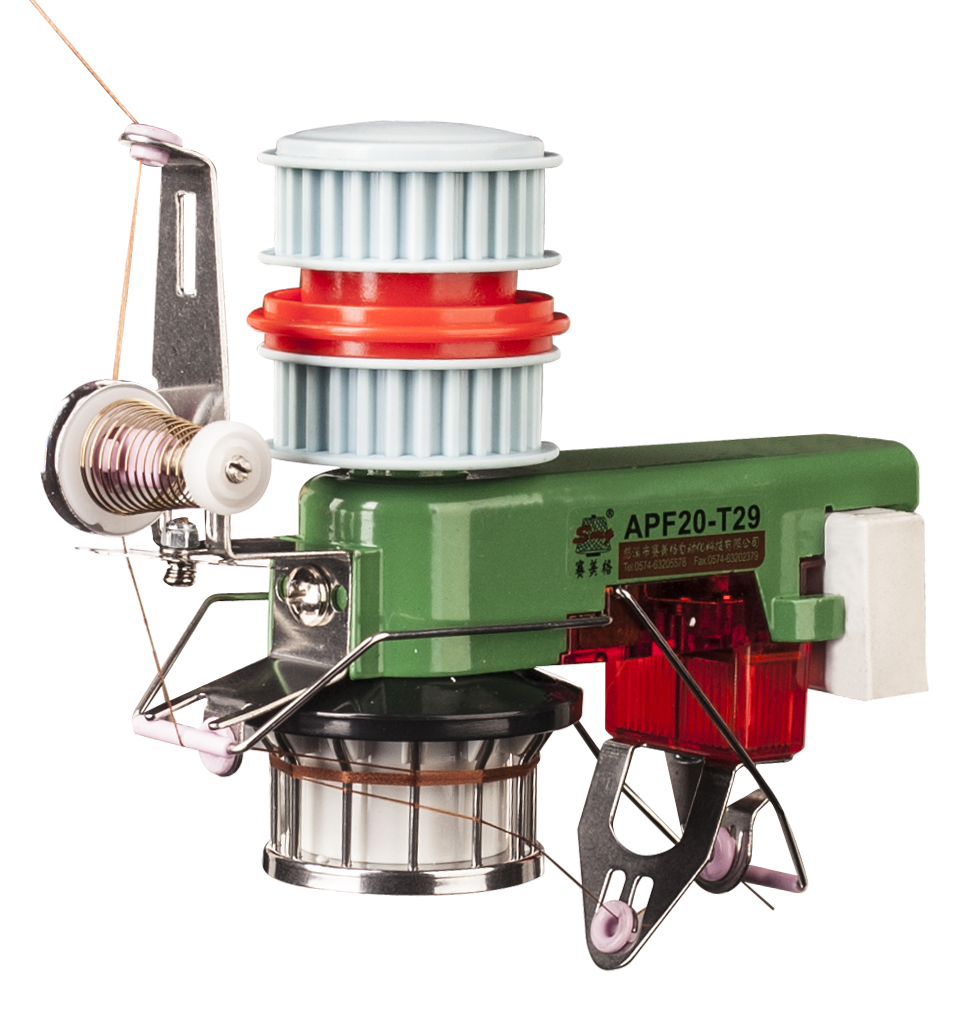

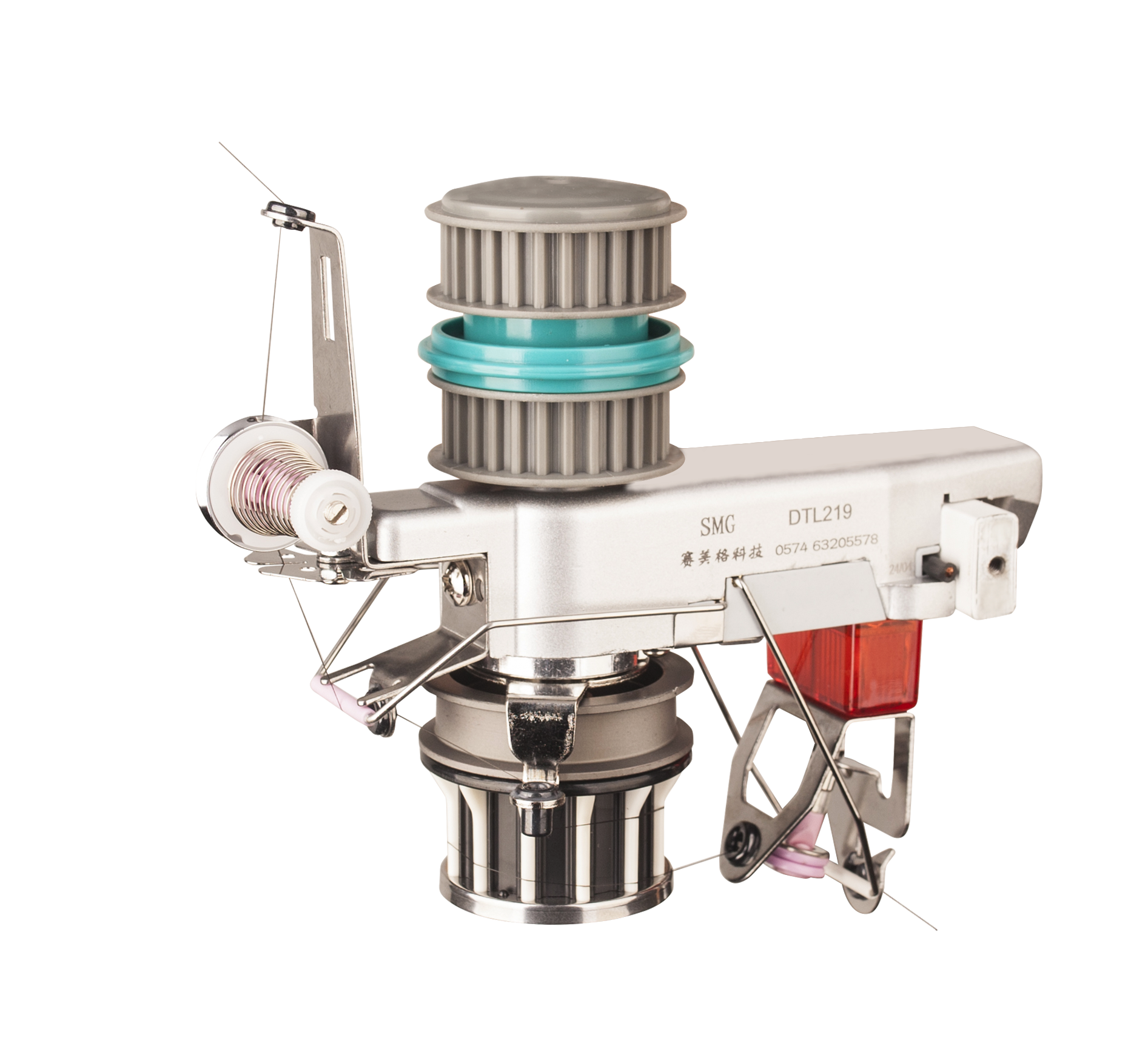

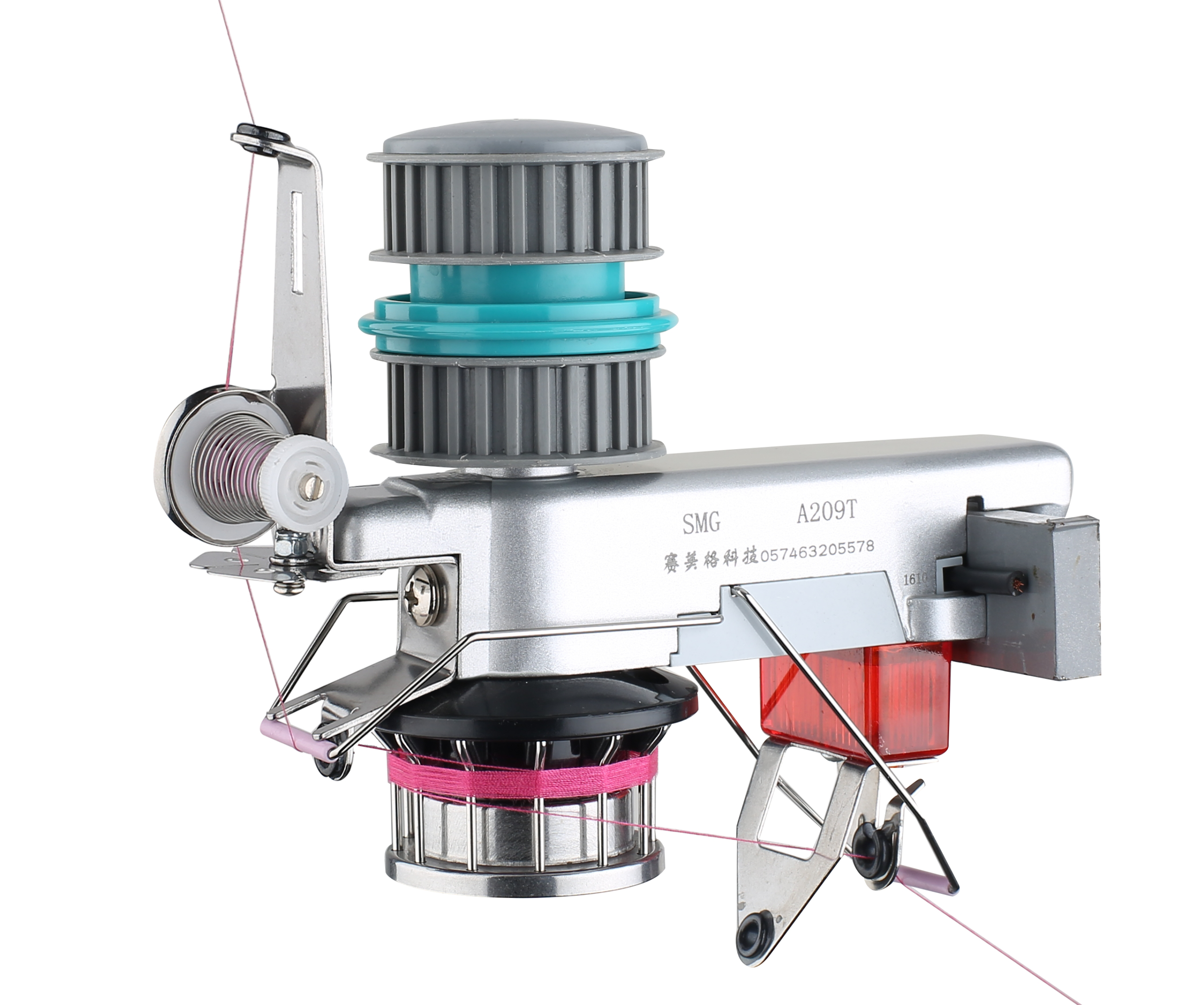

Positive feeders are essential in modern knitting machines, ensuring yarn feeds steadily and prevents tension issues.

A positive feeder1 regulates yarn tension, maintaining consistent delivery for smooth and precise knitting.

Discover how [positive feeders enhance knitting efficiency] and explore their various functions in different machine settings.

What is the function of the feeder line?

Feeder lines serve a vital role in yarn delivery, maintaining control and ensuring smooth operation.

[Feeder lines] deliver yarn to the machine, preventing tangles and maintaining steady flow.

Feeder lines work as a bridge between yarn storage and the knitting zone. They maintain a uniform feed rate, eliminating tension fluctuations. This precision is key to producing high-quality fabric.

Benefits of Feeder Line in Knitting

| Feature | Benefit |

|---|---|

| Tangle-free delivery | Smooth operation and fewer errors |

| Consistent tension | Better fabric quality |

| Reliable performance | Enhanced production efficiency |

What is the feeder in a circular knitting machine?

A feeder in circular knitting machines2 ensures yarn is supplied precisely where it is needed.

The feeder provides controlled yarn flow to needles, preventing slack or overtension.

In circular knitting, feeders maintain the rhythmic flow of yarn. They act as mediators, guiding yarn through cams to the knitting zone. By doing so, they ensure that the yarn is ready for each stitch, which is crucial for maintaining pattern consistency.

Types of Feeders in Circular Knitting

| Type | Purpose |

|---|---|

| Positive feeder | Maintains precise yarn tension |

| Negative feeder | Relies on external yarn pull |

Understanding feeder functionality allows operators to optimize machine settings for better output and reduced waste.

What is the function of VDQ pulley?

[VDQ pulleys] adjust the yarn length, playing a critical role in pattern precision.

VDQ pulleys control yarn delivery speed, adjusting lengths to meet pattern requirements.

The VDQ pulley system fine-tunes yarn length as per knitting needs. Operators can adjust its settings to match specific fabric designs. This adaptability ensures versatile production capabilities.

Key Features of VDQ Pulley

| Feature | Description |

|---|---|

| Adjustable length | Customizable for various patterns |

| Precision engineering | Consistent performance |

| Enhanced flexibility | Supports complex designs |

When combined with [positive feeders], the VDQ pulley creates a seamless interaction for efficient fabric manufacturing.

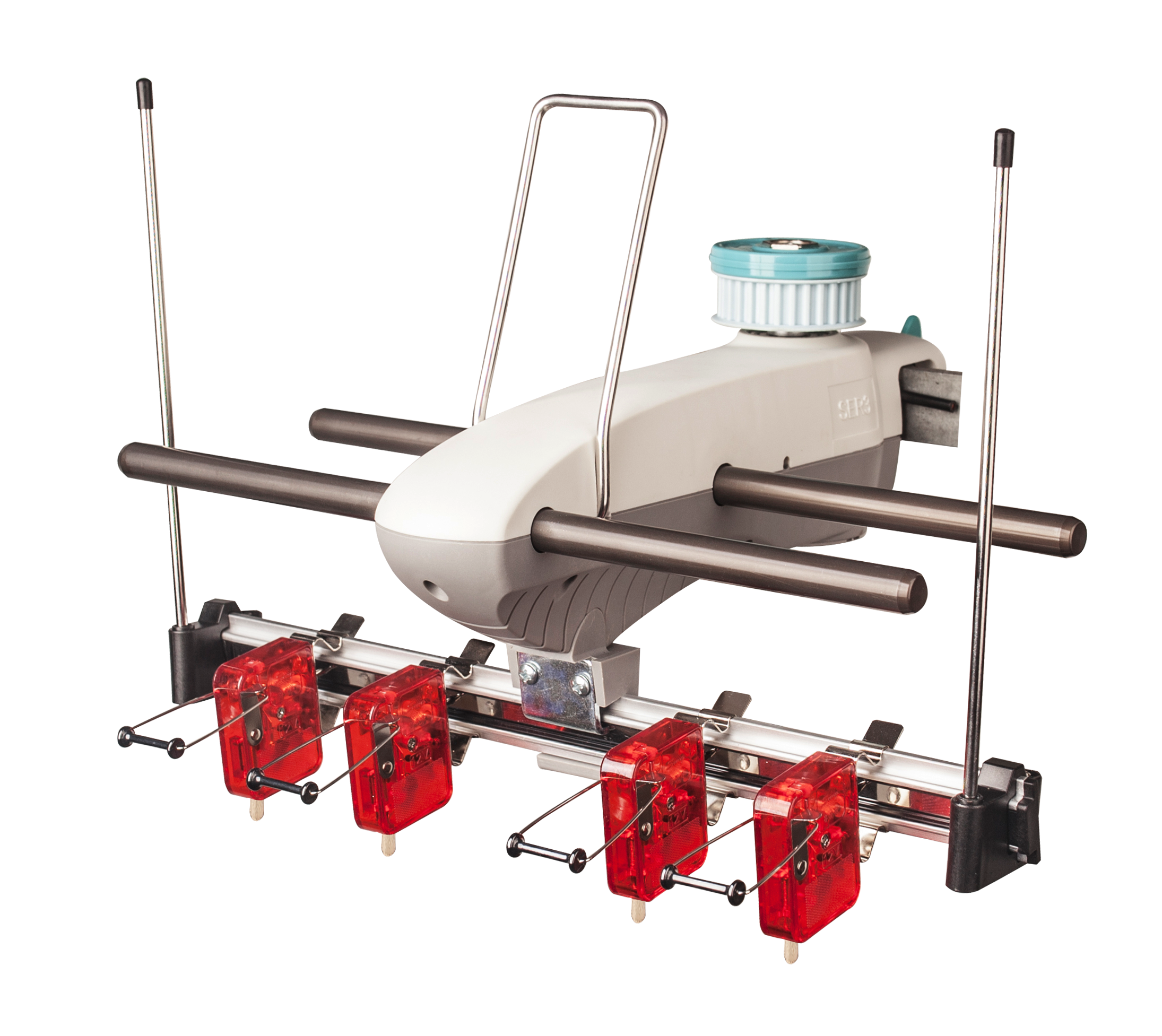

What is full feeder and half feeder?

[Full and half feeders] differ in their yarn delivery capabilities, impacting fabric texture.

Full feeders provide continuous yarn delivery, while half feeders alternate to achieve specific effects.

Full feeders deliver yarn consistently, making them ideal for plain fabrics. Half feeders, on the other hand, alternate yarn delivery, creating unique patterns and textures. This versatility gives designers more options in fabric creation.

Comparing Full Feeder and Half Feeder

| Feeder Type | Functionality |

|---|---|

| Full feeder | Consistent yarn delivery |

| Half feeder | Alternating yarn for patterns |

Understanding these feeder types helps operators and designers choose the right tool for their projects.

Conclusion

Positive feeders[^8] play a vital role in ensuring efficient, precise, and versatile knitting processes across various machine settings.